Tool changers enhance flexibility, at Scania

The efficient use of industrial robots requires tool changers, according to experience gained from Scania’s new bodywork facility in Oskarshamn, Sweden. When choosing supplier, quality and support are crucial factors.

Scania’s facility in the Swedish coastal town of Oskarshamn is the manufacturing site for all of the truck group’s cabs sold on the European market. Five workshops work in sequence with pressing, welding, primer painting, top coat painting and assembly.

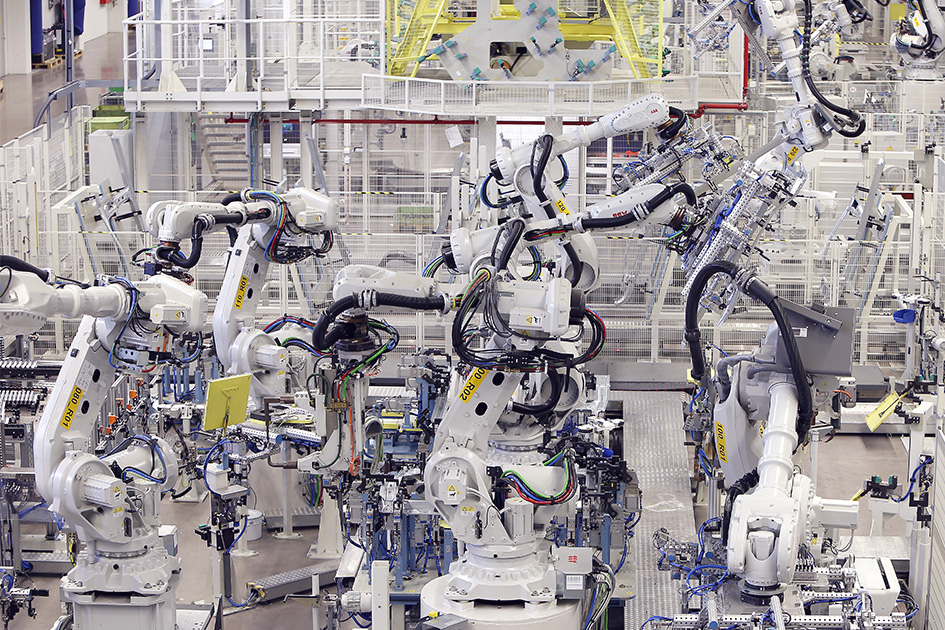

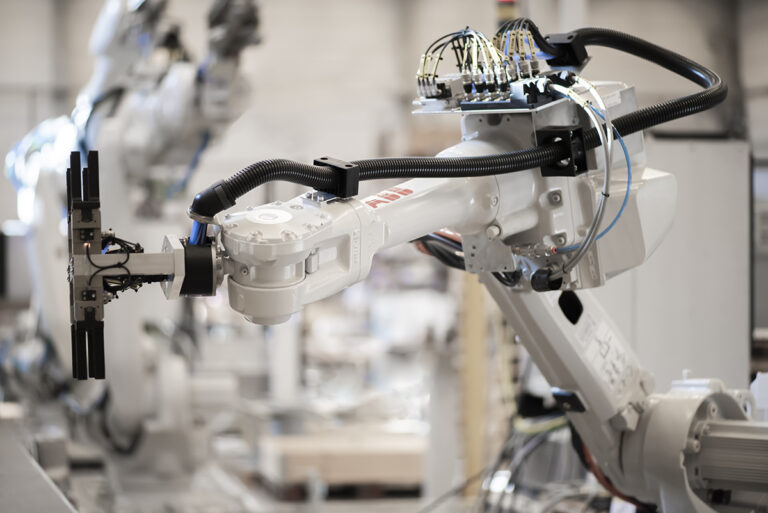

The new bodywork facility is spread over a floor area of 33,000 square metres and began operations in autumn 2016. The entirely new S and R models are manufactured here, for which not a single sheet of metal is similar to any used before. The facility is among Europe’s most modern. The working environment is calm, the air is clean, safety measures are strict and the noise level is low.

The high degree of robotisation is not just a prerequisite for Scania’s production volumes and financial viability, but also for the group’s renowned high and stable level of quality. Jörgen Boman, robot specialist at Scania:

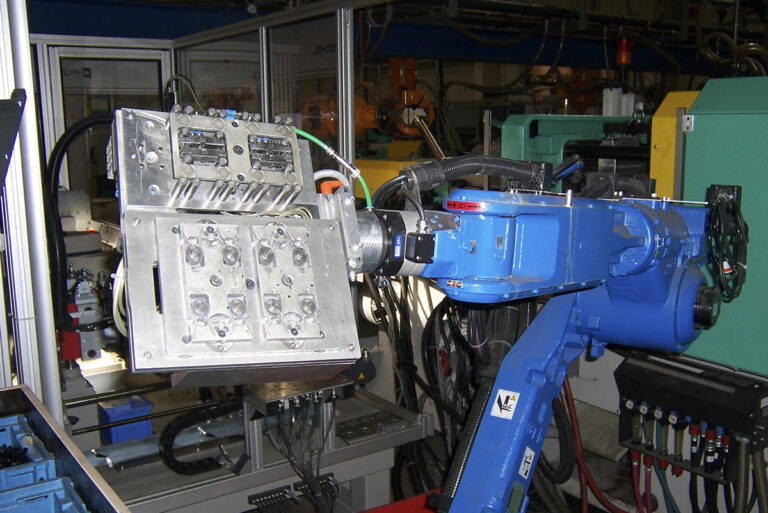

– Each of the 288 robots in place in the bodywork facility is equipped with RSP’s tool changer, either automatic or MQC. Production capacity has doubled.

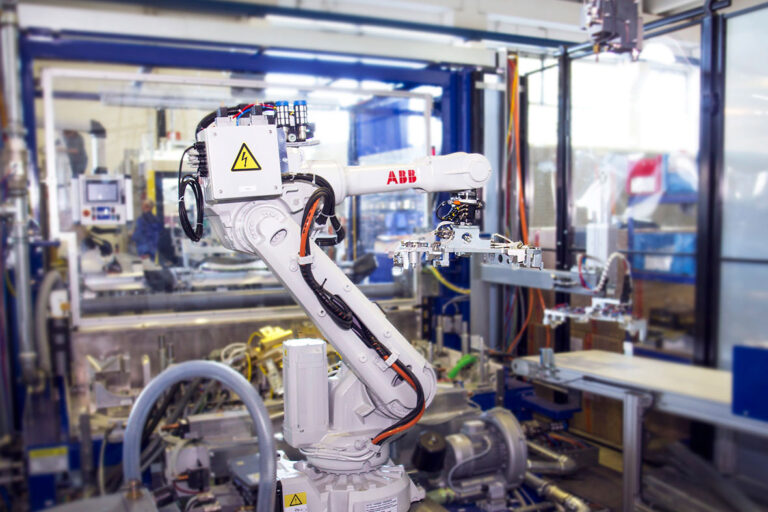

The 172 automatic changers consist exclusively of the TC480 model, designed for loads up to 500 kg and torque equivalent to 5,000 Nm. The modularity is extensive, and the peripherals can entail everything from materials handling to bonding and spot welding. MQC is an abbreviation of Manual Quick Changer, used to facilitate manual tool changing.

When choosing which tool changer brand to implement, quality and the availability of service and support were key factors. Jörgen Boman states:

– We tested a TC480 tool changer over a period of two years, and we never had a problem. Through RSP we have access to training and rapid support. If something breaks down, we can have a replacement part delivered here by taxi within four hours. The service and support operations are a real trump card.

– Our older facilities are also kitted out with RSP’s tool changers.

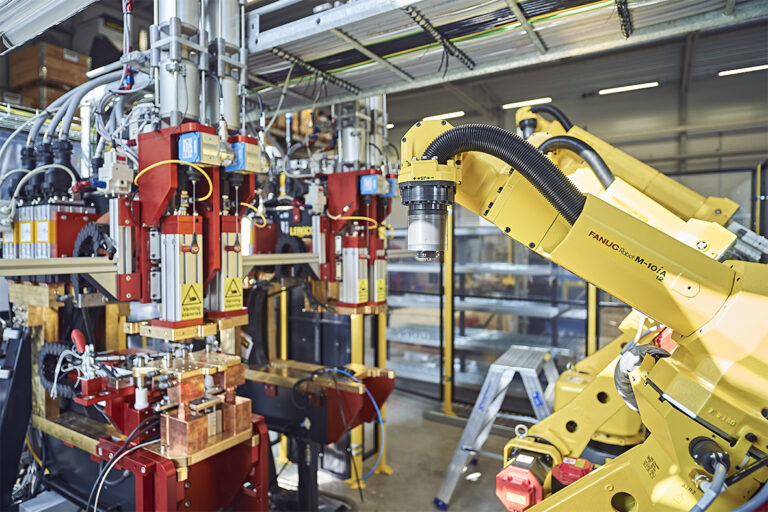

Why are tool changers used? The obvious answer is that it allows more work to be done by fewer robots, entailing a reduction in investment requirements. But the effects are more far reaching than just this:

– Automatic tool changers save a lot of space. More robots need more room. Without tool changers, more activities are needed, which leads to more fixtures, larger distances, more handover points, et cetera. It’s like a snowball that starts rolling and gets bigger and bigger.

In 2011, Scania initiated its project of designing the new bodywork facility. A working group was put together from different parts of the company, gathering individuals with complementary competence.

– We asked ourselves what equipment would be needed to produce the new cabs and considered a few alternatives. What robots would be needed? What specifications would be required? Things change as the work progresses. We also had to ask ourselves where our suppliers were located, if we had previously received good support, if they had a Swedish representative?

And the conclusion in the matter of tool changers?

– We’ll be sticking with RSP, says Jörgen Boman