CiRO, flexible and compact, at Löfqvist Engineering

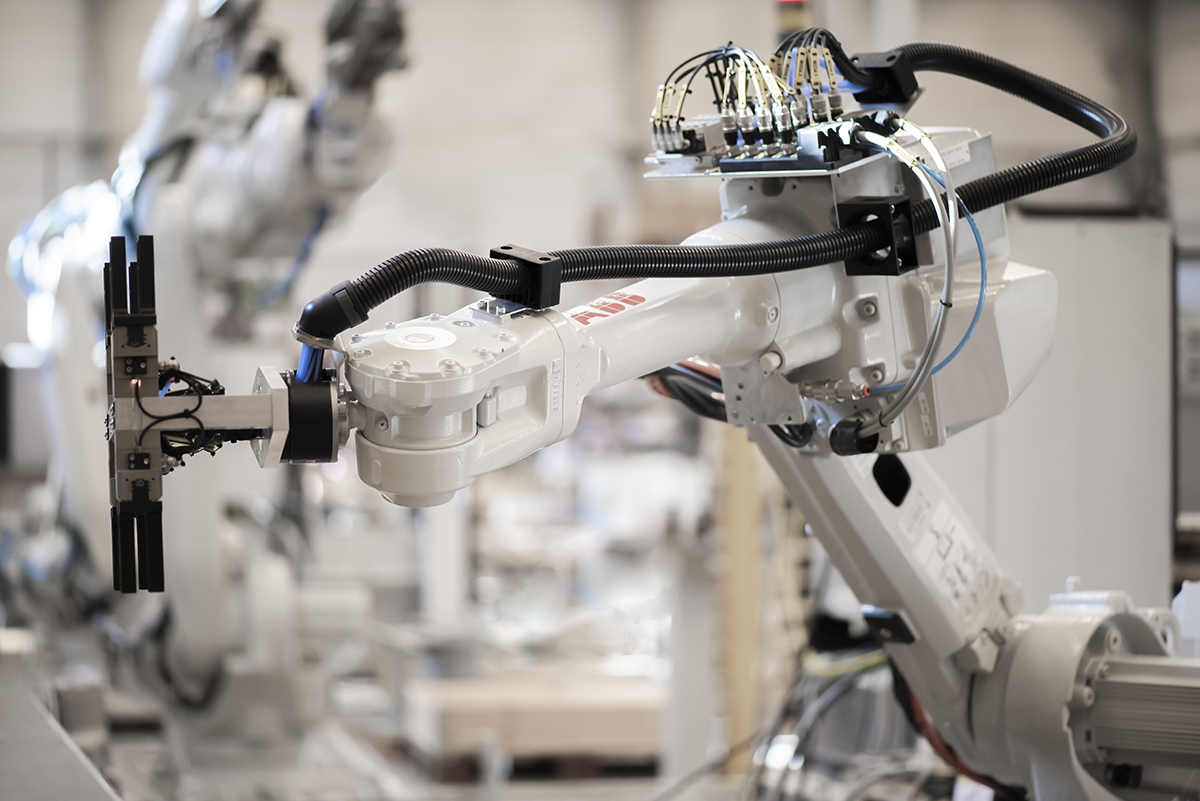

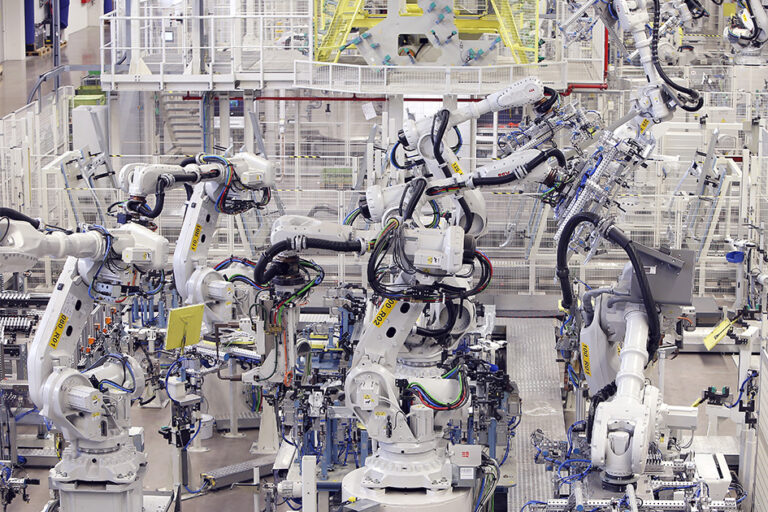

Rotations up to 500 degrees around axis 6. Free choice of cables and hoses. Withstands wear, dust and damp environments. Compact and cost-efficient. We have been talking CiRo with Löfqvist Engineering, a company based in central Sweden that has delivered robot solutions primarily to the automotive industry for more than 40 years.

Löfqvist Engineer Morgan Johannesson always makes the greatest possible simplicity his starting point. Morgan considers flexible standard technology to be preferable over unnecessarily complex solutions.

“We design ready-to-go systems,” he says. “They consist of one or more robots with peripherals which we equip with tools and grippers. It’s often a matter of a material, entering through a line or pallet, which is transported by a robot between stations for processing and measurements. Safety is a major concern as well.”

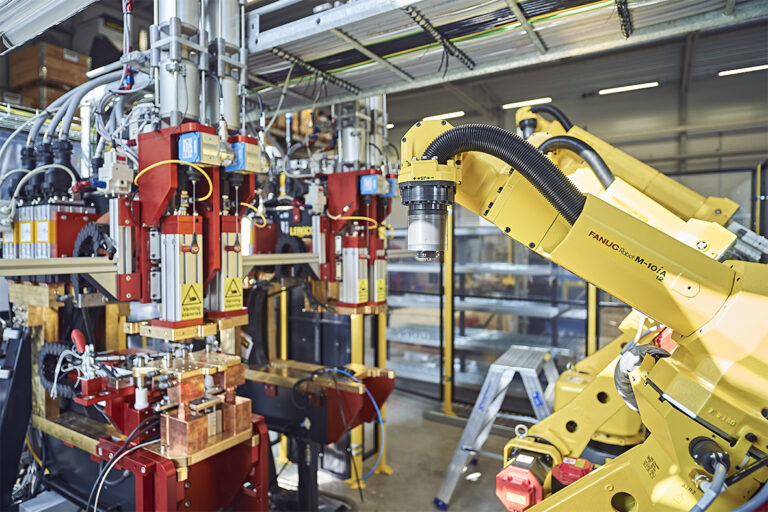

It was through a collaboration with Löfqvist that RSP developed the compact and mechanically less complicated CiRo. With CiRo, cables and hoses can be connected directly to tools and Tool Changers in a way similar to robots with internal cabling. The motion capabilities are excellent; around axis 6, rotations of 500 degrees are allowed. Cabling for signaling, data and power, as well as air and water hoses, can be freely combined.

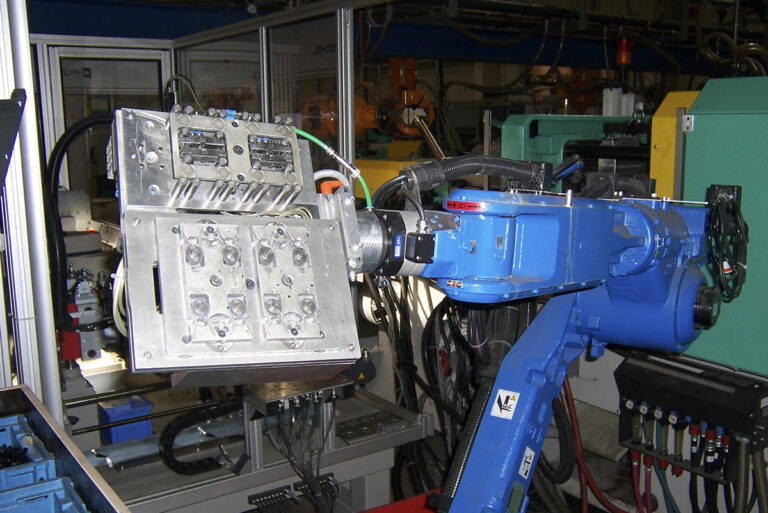

Initially, it was Morgan Johannesson who came up with the ideas that became CiRo during a project designing a robot cell within a very narrow workspace.

“Air, water and electrical power was to be transferred to the tool,” he says. “The limited space had to be scraped, cleaned by compressed air, and sprayed.”

The task was challenging, the space was too small to allow external cabling, and there was not enough room for any swivel-based solution. With cables and hoses gathered in the newly constructed CiRo, the task was carried out.

“A great example of CiRo’s compactness and flexibility,” says Morgan.

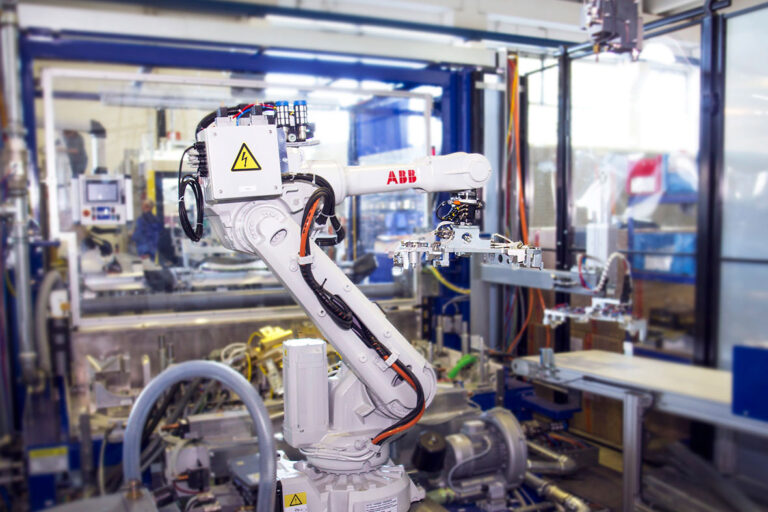

He points out that in addition to the obvious advantage of being cost-efficient, CiRo is less sensitive to wear, dust and moisture penetration. The greatest gain, alongside good motion capabilities, is the free choice of electrical signals and power, of air and water channels.

“Air and sensor cables can be rearranged as required,” says Morgan. “If any hose or cable fails, it’s easy to replace it.”

But the benefits of avoiding external cables and hoses do not stop there.

“With the cables hanging freely, centrifugal forces become substantial, such movements may be difficult to simulate,” says Morgan. “By eliminating concerns about movement of hanging cables during testing, you can avoid a lot of manual tasks and save a considerable amount of time.”

Morgan also points out the problem of loose cables that stretch out over time, with the inherent risk of them becoming entangled and causing operational disruptions.

“Because CiRo’s cabling is centered, faster movements can be allowed. With CiRo, the programmers do not need to take into account the cabling; you do know where they end and can simulate the movements in a robot studio.”

Morgan Johannesson also mentions that Tool Changers can be mounted on the CiRo:

“And not just single Tool Changers, if you like you can even have solutions with multiple changers, up to four of them.”

Why has Löfqvist chosen RSP as their supplier?

“Everything works smoothly with RSP as our preferred supplier,” says Morgan. “Your products are excellent. And you at RSP listen to us when we need something special, something different.

“Your hose packages are well designed and really work well, and at RSP you are knowledgeable of all robots and robot mounts. It’s good working with a specialized company focused on robot peripherals,” he adds.

“And you’re responsive regarding our needs. That you care about what we need is very important to us.”