Revolutionize Your Cobots - Introducting the Next Generation of Tool Changers, CoboShift

The rise of collaborative robots (cobots) has transformed the robotics landscape, pushing the boundaries of automation and human-robot interaction. Recognizing their growing impact, we've developed a new line of tool changers specifically designed to enhance the versatility and efficiency of cobots. These innovations reflect our commitment to supporting the evolution of robotics, empowering industries to achieve new levels of productivity and flexibility.

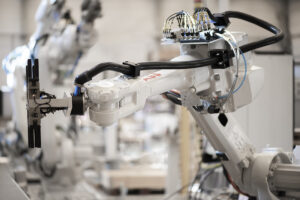

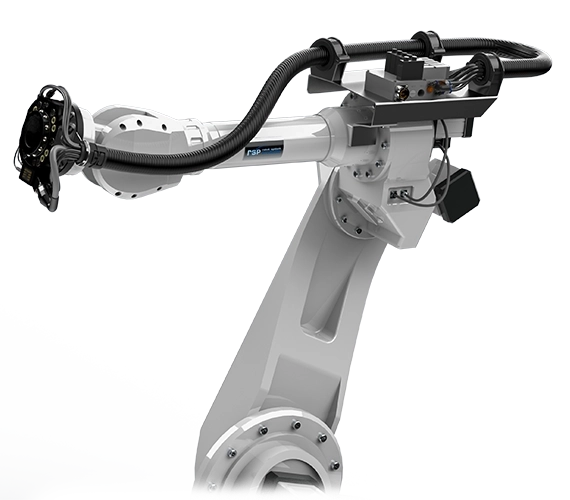

Complete dressing for your robot

As a leading supplier of peripheral equipment for industrial robots, RSP provide a wide range of units to completely dress your robot according to any application demands. We provide everything from end-of-arm units to hose packages, valve units and other components.

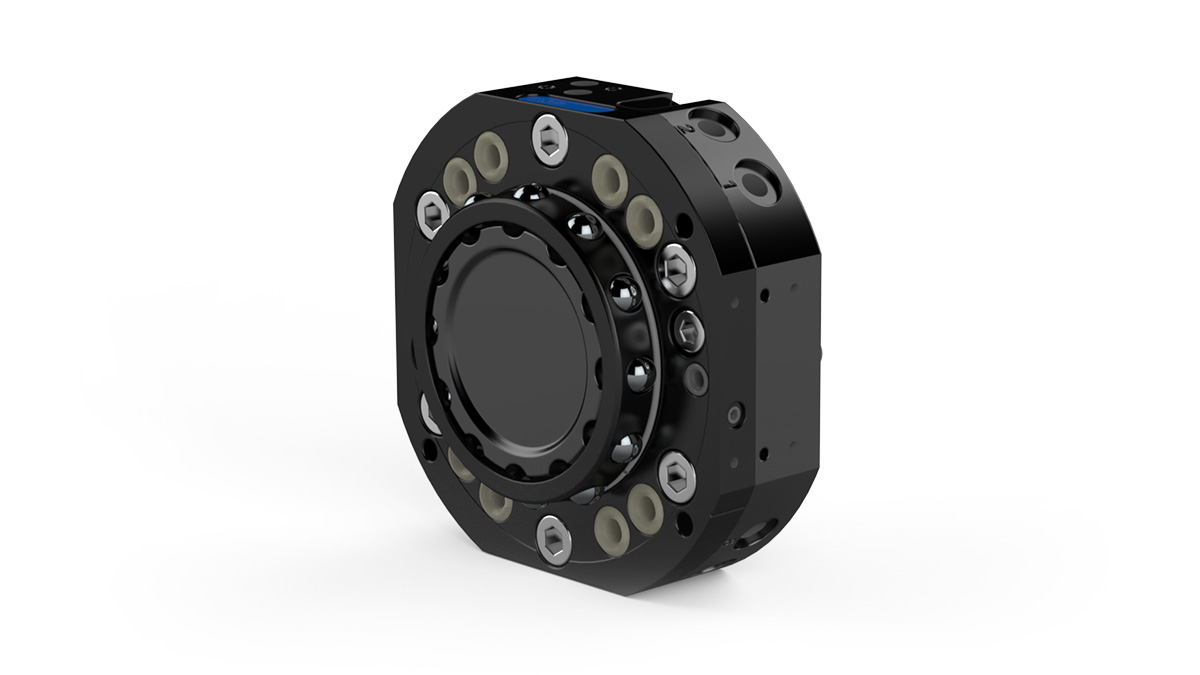

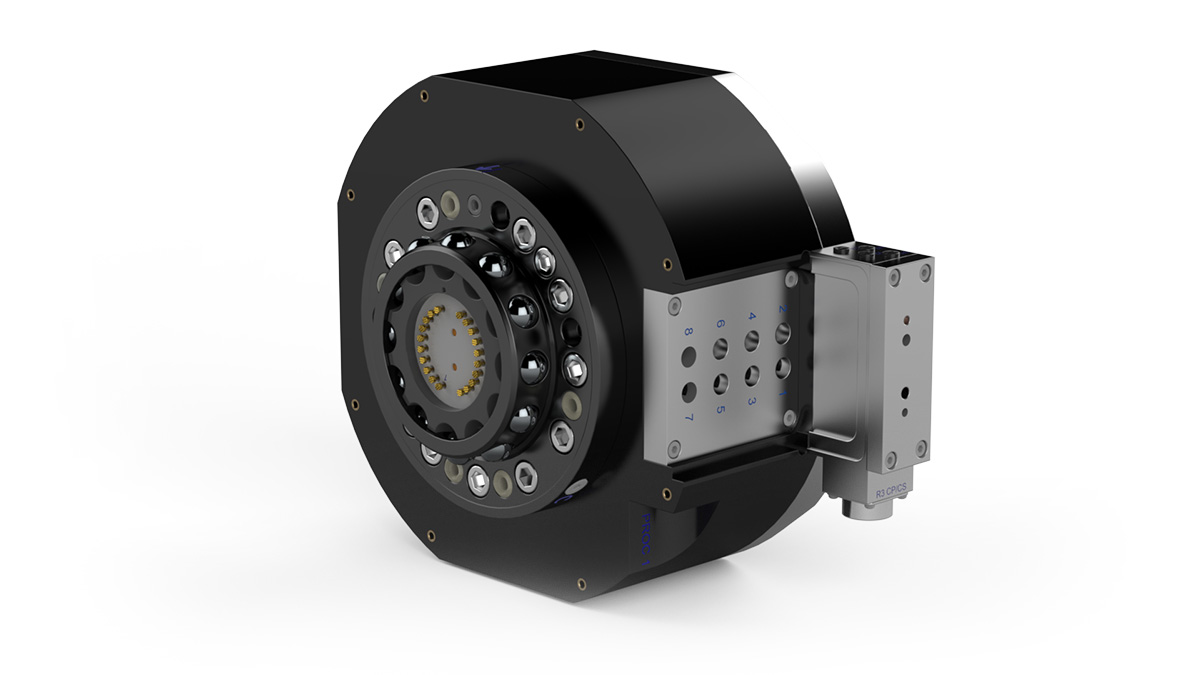

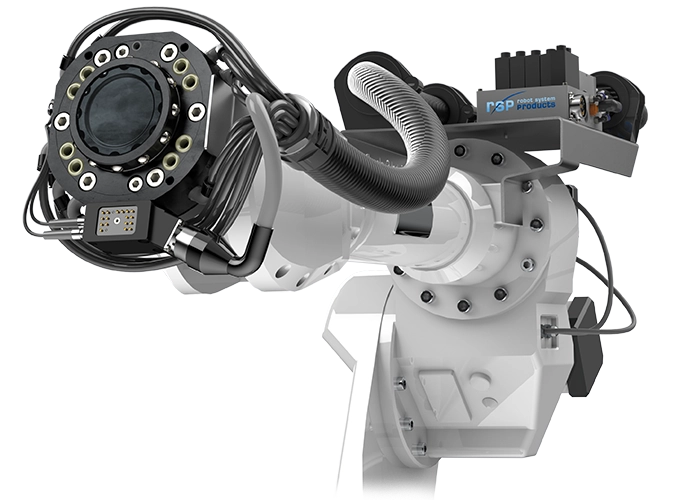

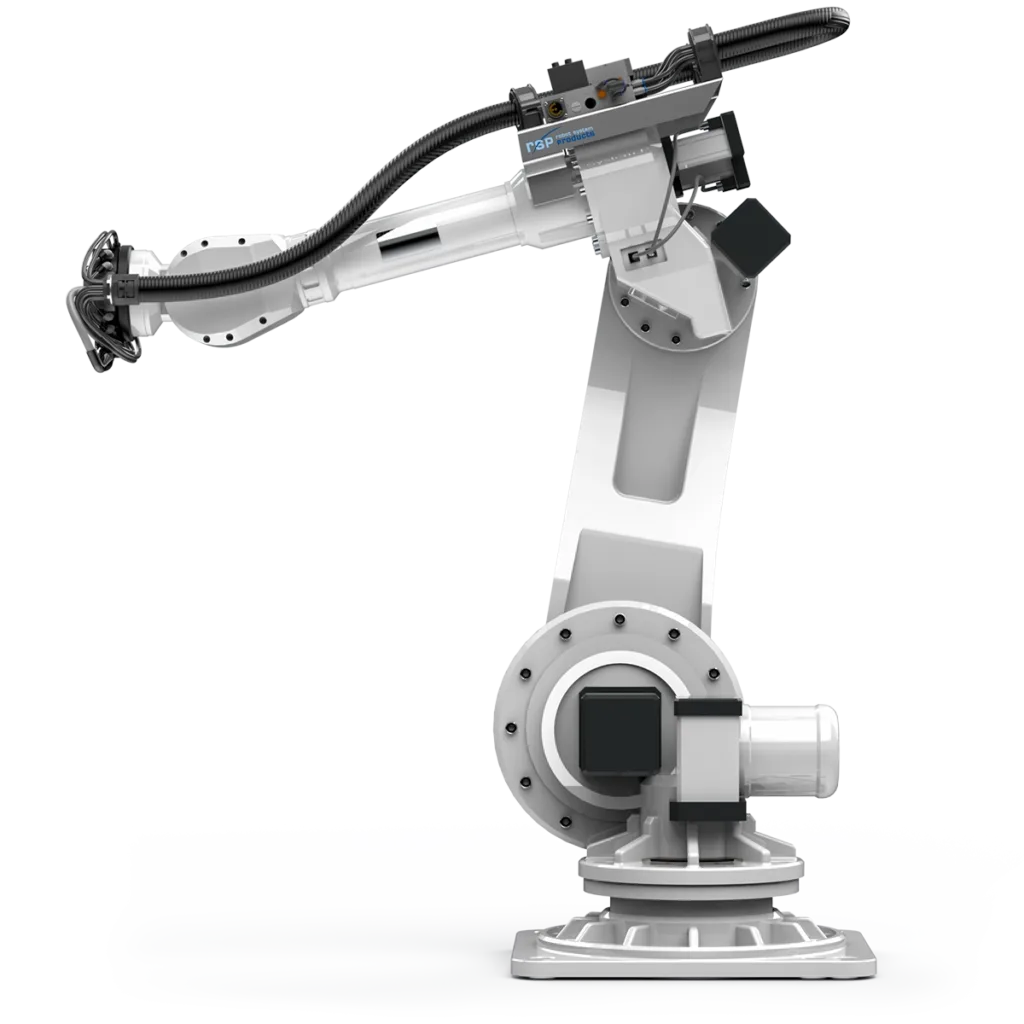

High performance robotic tool changers

When it comes to utilizing the robot's performance when it comes to end-of-arm tooling (EOAT), tool changers are invaluable due to their versatility and efficiency. All tool changers from RSP comes with our patented locking system TrueConnect™.

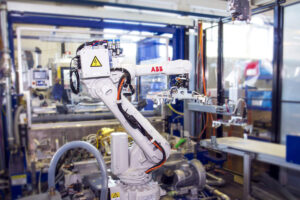

Absolute accuracy calibration

The Swedish tech-company Cognibotics have developed a groundbreaking system for absolute calibration of all major robot brands on the market. Robot System Products are now providing this solution to the global market. A complete product palette of equipment and software for absolute accuracy calibration, for robots and cobots.

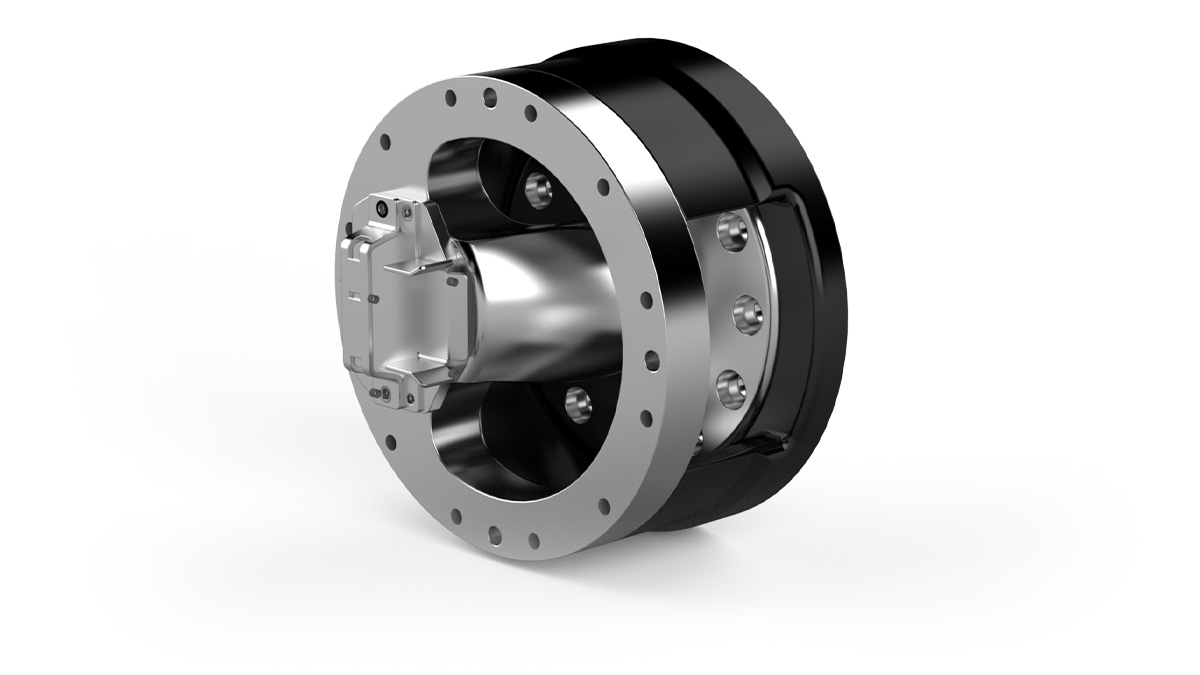

Hose packages for longer lifetime

With our roots in the robot world from many years, we know how much trouble a bad designed hose package may cause. Our design department always have long lifetime as priority when it comes to developing new hose packages. Today we provide hose package solutions for more than 100 robots.

Improving Robot Flexibility

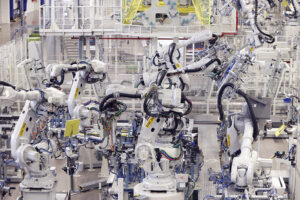

Robot System Products is a global leader in high-performance industrial robot accessories, providing tool changers, swivels, hose packages, valve units and complete packages to dress robots for different applications.

RSP stands at the forefront of the industrial automation industry as a renowned global leader in delivering cutting-edge solutions for enhancing the performance and versatility of industrial robots. Among its diverse range of innovative offerings, tool changers take center stage due to their unmatched benefits for modern manufacturing processes.

One of the key reasons why tool changers are highly regarded in the industrial robotics realm is their unparalleled versatility. RSP’s tool changers allow robots to effortlessly switch between different tools or end-effectors, such as grippers, welders, drills, or other specialized equipment, with minimal downtime. This enables robots to perform multiple tasks or handle various products without requiring time-consuming manual tool changes, thereby maximizing productivity and throughput.

By choosing Robot System Products and our innovative accessories, such as tool changers, you can expect a higher return on investment (ROI) through increased productivity, enhanced safety, and future-proofing capabilities for your industrial automation processes. RSP’s cutting-edge solutions empower you to optimize your robotic systems for maximum performance and efficiency, positioning you at the forefront of modern manufacturing.

PRIORITIZING SAFETY

Our exclusive and patented safety solution guarantees continuous supervision of the tool changer, ensuring optimal safety at all times.

BUILT TO LAST

Our patented locking mechanism is built to endure, providing you with reliable performance year after year. With TrueConnect™, you get a lifetime warranty.

SMART INVESTMENT

Our customers choose RSP for the exceptional quality and performance of our products. Trustworthy solutions, always.

DEDICATED SUPPORT

Our service and support team is always ready to assist you whenever needed. At RSP, your trust and satisfaction are our top priorities.

A global provider of high performance robotics products

All our tool changers feature the patented locking device, TrueConnect™. It reduces play to the minimum and enables absolute alignment repeatability throughout its lifespan. With its unique design, it does not require exact alignment before docking with different tools. The principle behind the locking mechanism is the uniform distribution of load, obtained by pressing locking balls into spherical grooves in the tool attachment. Industry leading longevity and positional flexibility when docking.

Come and meet us at the following events

Discover our products

Latest News

Video: RSP at Automatica 2025

We are back after an exciting week in Munich for this years Automatica. Big thanks to all visitors during the week. Watch the short recap...

Read MoreIntroducing CoboShift – The new generation tool changers for collaborative robots

We are pleased to announce the launch of CoboShift, a brand new product family of tool changers designed specifically for collaborative robots (cobots). The new...

Read MoreThis was Elmia Automation 2024

Wow! It was great to experience a trade show like this in Sweden. During the week we had a lot of visitors in our stand,...

Read MoreCase Studies

CiRO, flexible and compact, at Löfqvist Engineering

Rotations up to 500 degrees around axis 6. Free choice of cables and hoses. Withstands wear, dust and damp environments. Compact and cost-efficient. We have...

Read MoreTool changers enhance flexibility, at Scania

The efficient use of industrial robots requires tool changers, according to experience gained from Scania’s new bodywork facility in Oskarshamn, Sweden. When choosing supplier, quality...

Read MoreGluing made easy, at Frimo

When the German company FRIMO established a plant for gluing interior fittings for the car industry, the opportunity to fully utilize its robots’ mobility was...

Read More