Gluing made easy, at Frimo

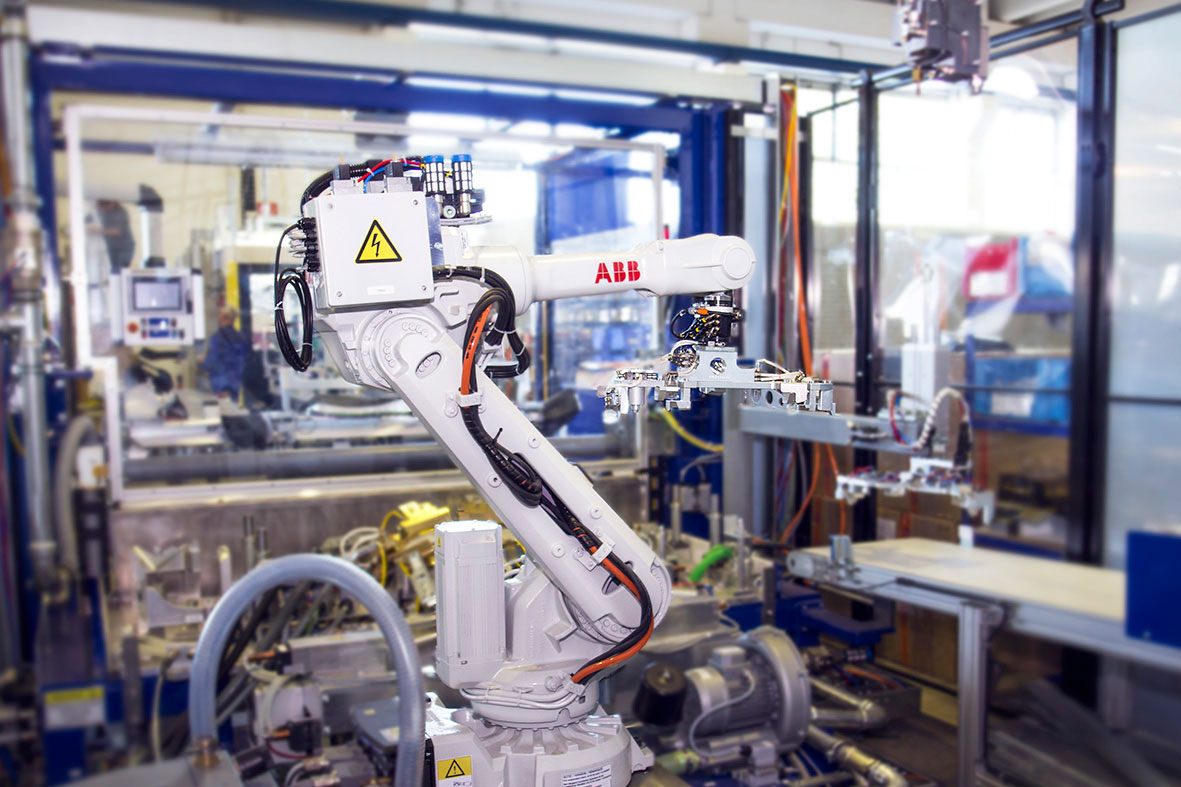

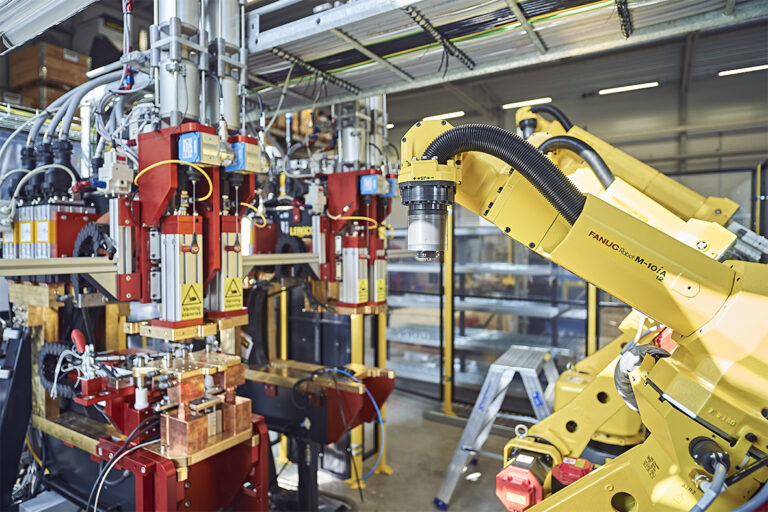

When the German company FRIMO established a plant for gluing interior fittings for the car industry, the opportunity to fully utilize its robots’ mobility was decisive. Equally significant was the capacity to automatically change tools with precision and maintained function. The choice fell on the swivel tool changer from Robot System Products.

FRIMO – a company that specialises in production engineering within the plastic industry – is located in the idyllic south German region of Berchtesgadener Land. It is a market leading supplier of production tools and solutions for thermoforming, laminating and edge folding of plastic components. The requirements on robot flexibility and free movement are vital in their applications, above all this applies to gluing where an even and exact distribution is crucial for the quality. With full precision, the glue dispenser must follow the contours of the interior fittings without cables and hoses constituting an obstruction. The fact that components for left- and right-hung car doors can be mounted with the same equipment is a benefit.

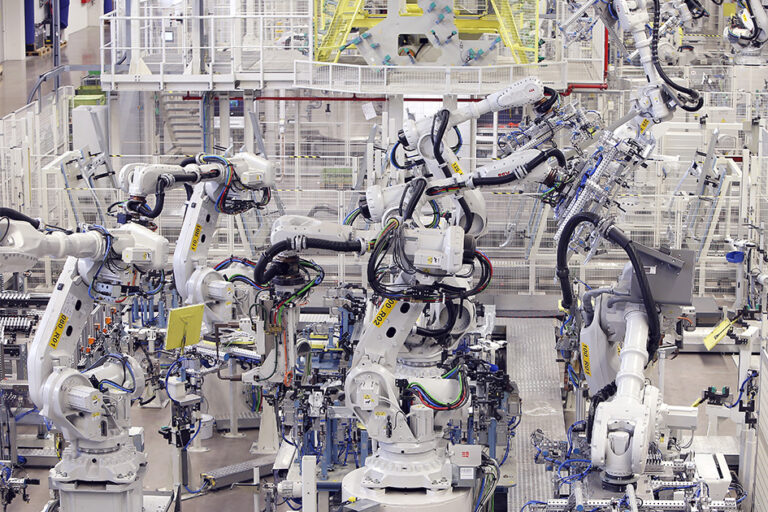

For full accessibility, 6-axis robots which can perform their tasks without restrictions are needed. The high level of complexity also requires axis 6 to be fully utilized without being restricted by the hose unit. Automatic tool changing, with maintained function and precision, are necessary from an efficiency perspective. It is here the benefits of RSP’s combined technology for free rotation and tool changing comes into play.

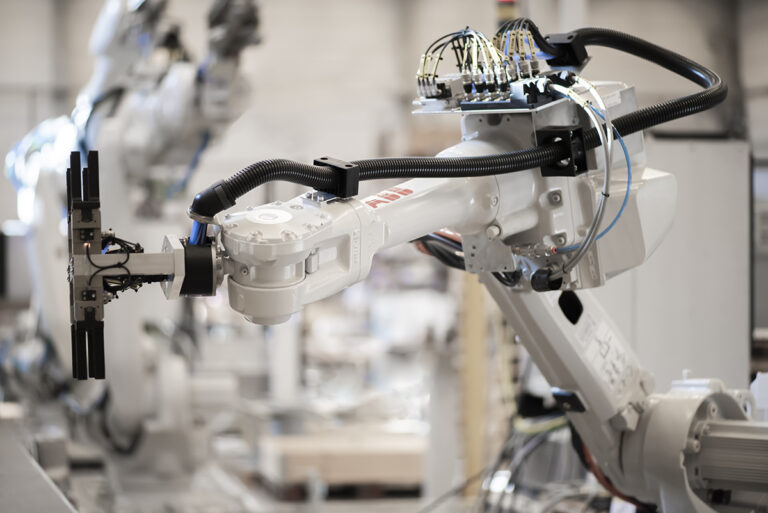

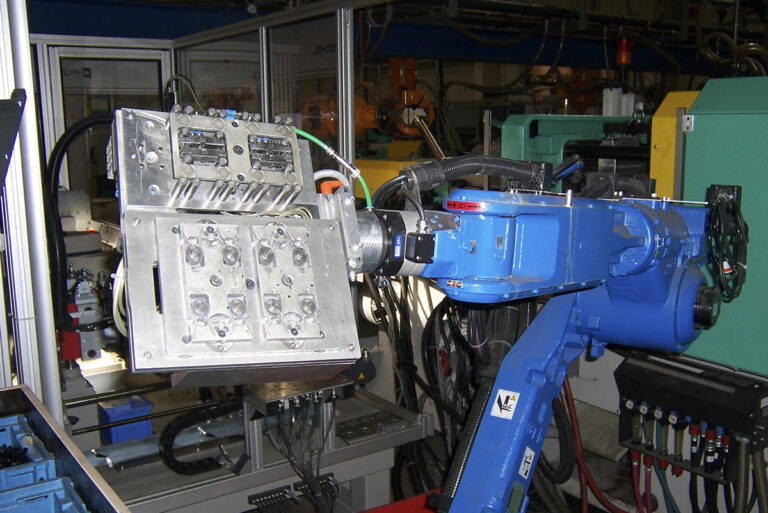

With RSP’s swivel tool changer, compressed air and electrical signals are transmitted to the robot’s tool without affecting its capacity to move. The hose unit stays close to the robot’s arm even during complicated manoeuvres. Not only analogue signals can be transmitted without loss of quality but also digital bus communication. The patented locking mechanism TrueConnect™ guarantees precision and reliability during tool change.

When FRIMO established a plant for an Italian manufacturer of door parts, the swivel tool changer STC20-4E was selected. With STC20-4E the 6th axis can rotate freely without being obstructed by external hoses and cables. Internally 4 pneumatic channels and 8 electrical signals are transferred. It is designed for a load of 20 kg under continuous operation. In addition, RSP offers swivel tool changers for handling weights between 5 and 350 kg.

Simon Pöllner, responsible for design of production plants at FRIMO, is satisfied with the solution. With RSP’s technology complicated methods for handling freely hanging cables and hoses are avoided and no additional space needs to be reserved. The programming becomes easier and the hose unit’s service life increases significantly. An additional benefit, he emphasises, is the swivel tool changers’ compact design and the fact that the centre of gravity is close to the robots’ turning disc.