Unlocked Accuracy - Powered by Cognibotics

Robot calibration for absolute accuracy

Robots are fantastic when it comes to automating production and making it more effective. However, we can probably agree that the accurate positioning sometimes is just not enough. Thanks to the calibration systems from Cognibotics it is now possible to make your robots more accurate, both in positions and linear movement.

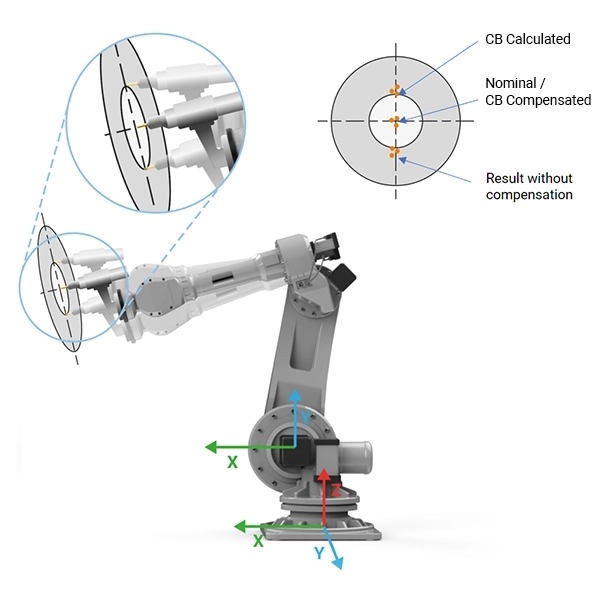

This great solution is available as various packages for both industrial robots and cobots. For an archer to hit the target he needs to aim higher before taking the shot. We are going to show you how we have implemented this into this robot calibration system.

Calibrate – Compensate

- Modify target coordinates through postprocessing of the robot programs to increase accuracy.

- Compensation is based on the identification from calibration.

- Compensates in the whole of the robot's workspace and and in different robot configurations.

- Adapts to different payloads to reach the same accuracy with all loads.

Absolute accuracy calibration explained

Improve Operational Reliability

Calibrate Robot after repair -> Minimize downtime by being able to use old programs without adaptation.

Identify changes in robot properties over time –> Predictive.

Quick and predictable Deployment

Offline programming without manual ” touch-up” -> Lower robot programming time.

Real digital twin, make your real robot behave like your simulated -> Lower commissioning time in new robot cells.

Improved tolerances & Quality

Use robot to new and challenging applications – 3D print, Laser/Water cutting, Laser Welding, etc.

Calibrate external axes – Create global accuracy for robot together with linear tracks, positioners, etc.

Robot System Products offer

Industrial Robot Solution

Our solution for calibration of industrial robots consist of three different applications. Arm calibration, optical calibration and sensor calibration. Everything connected to the sofware from Cognibtoics.

Cobot Solution

The cobot solution for calibration involves a unique clamping plate supplied woth RSP tool changer and the CogniCal, calibration software. It is a bolt-on solution for UR-robots but can be easily adapted to other cobot brands.

RSP Cognibotics Calibration Highlights

- Extensive parameter set

- Calibration from base to flange (normally från axis 1 to 6)

- Compensates for different payloads, forces and bending

- Several integrations possibilities, from simple offline addon postprocessing, to fully integrating libraries in customers control systems

- External axis support

Calibration technology

Robot Calibration Technology

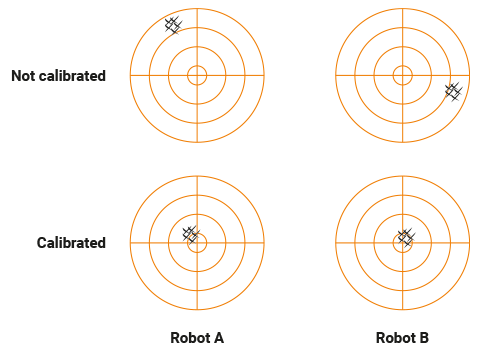

Repeatability vs Accuracy

Nominal robots

- Good repeatability

- Bad absolute accuracy

Calibrated robots

- Good repeatability

- Good absolute accuracy

Robots A and B are examples of two robots of the same brand and model.

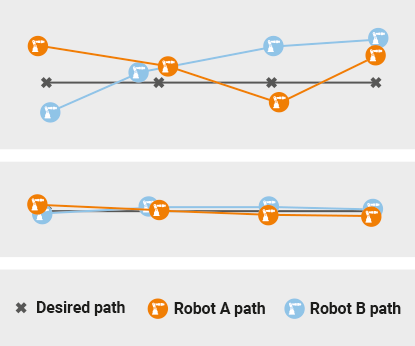

Accuracy affects points as well as paths

Nominal robots

- Path deviates between robot individuals

- Robot-specific program tuning is needed

Calibrated robots

- Same path by different robot individuals

- Robot-specific tuning is rarely needed