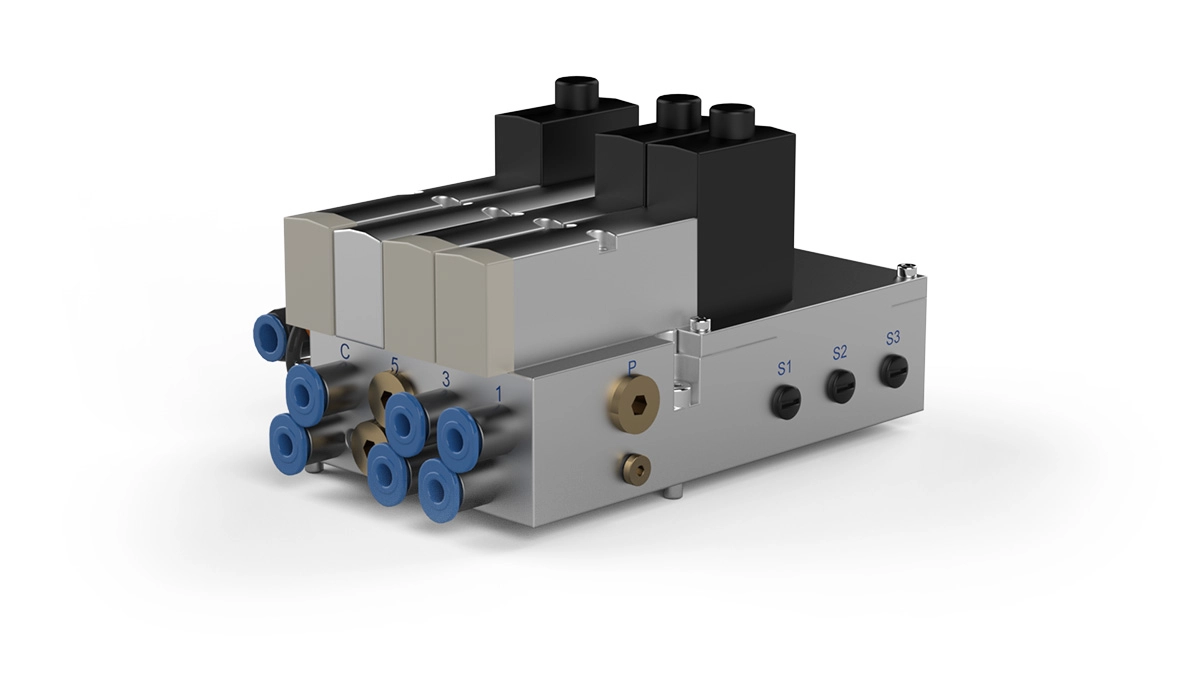

Small valve unit with 3x valves (for tool change)

- Small valve unit three valves

- One valve is dedicated for tool change

- The tool change valve shuts off the air to the other valves on tool change

- Built in connection box for I/O signals

- Standard ISO15407-2 18mm IE interface

The RSP valve unit is connected to the robot signal/air interface. The signals from the robot are connected to the terminal inside the valve unit. Connections for up to four valves with two solenoids each are prewired. On the valve unit a contact is mounted for transferring signals to/from the tool mounted at the wrist of the robot. As standard Festo-valves are used. Other brands can be fitted on request.

| Working temperature | +10°C – +50°C | 50 °F – 120 °F |

|---|---|

| Weight | 1.4 kg | 3.1 lb |

| Air connection, inlet | Ø8 mm hose (1x) |

| Air connection, outlet | Ø6 mm hose (6x) |

| Air channels dedicated | 2 (TC open and TC close) |

| Air channels available to tool | 4 |

| Max air pressure | 10 bar | 145 psi |

| Air quality | Oil-clean and waterless filtered air, with max 25µm particle content |

| Valve size | ISO15407-2 18 mm |

| Valve type | 1 x Tool change valve 5/2 Monostable, 2 x Directional valves 5/2 Monostable |

| IP Class | IP 54 |

| Signals total | 11 |

| Signals dedicated tool side | 2 (TC opened, TC closed) |

| Signals available to tool | 7 |

| Voltage, valves | 24 V |

| Connection input | 1x M16x1.5 for cable gland, 1x M20x1.5 for cable gland |

| Connection output | M12 contact 8p Female |

| Rated current | 1.5 A |