Automotive industry solutions

The use of robotics in the automotive industry has revolutionized the way vehicles are manufactured and assembled. Robotics technology has made the production process faster, more efficient and cost-effective, leading to an increase in the output of vehicles and improvement in their quality.

Modern automotive industry needs fast and flexible solutions to keep the overall costs down. Thanks to our in-house development, we can supply high-performance products using modern technology. As a result of increasing your robots flexibility and utilization, you get an effective production chain in vehicle manufacturing.

Other important parts of modern manufacturing is environmental quality and safety of operations. Robot System Products have a high standard of robotic accessories. Our design department has developed products with integrated safety supervision along with other important features. Regulations in safety are always top priority and we constantly keep tracking on the latest directives.

General automotive operations

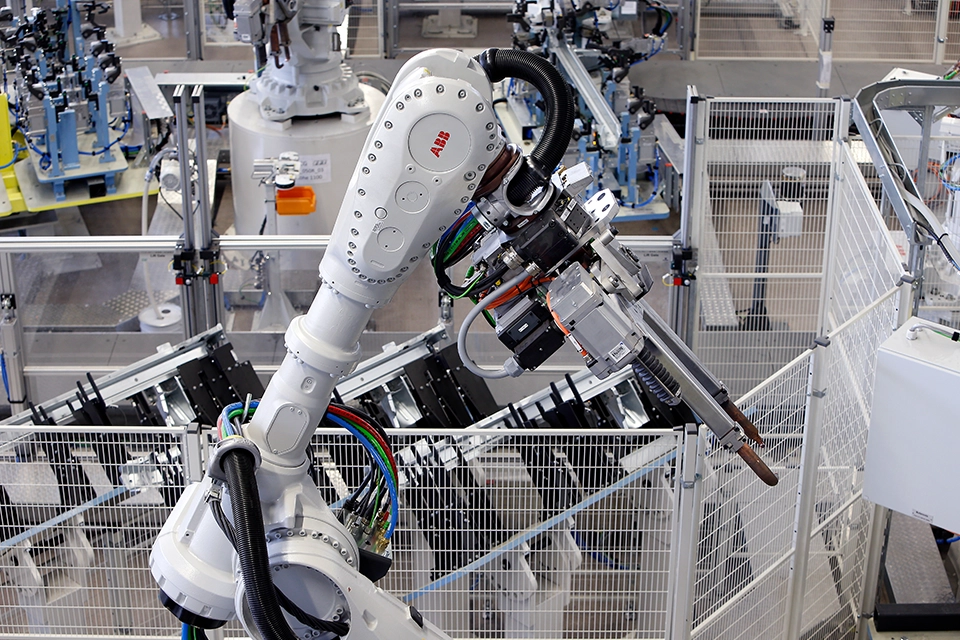

One of the areas where robotics is extensively used in the automotive industry is in the production of car bodies. Robotics technology has made it possible to automate repetitive and hazardous tasks, such as welding and handling heavy machinery parts, which was previously performed by human workers. This has improved the speed and accuracy of the production process, leading to better quality components, and reduced the risk of workplace injuries. Traditionally, welding procedures, and most of all spot-welding are common used process in bodyshop factories. RSP have a complete assortment of Tool changers well suited for these types of applications.

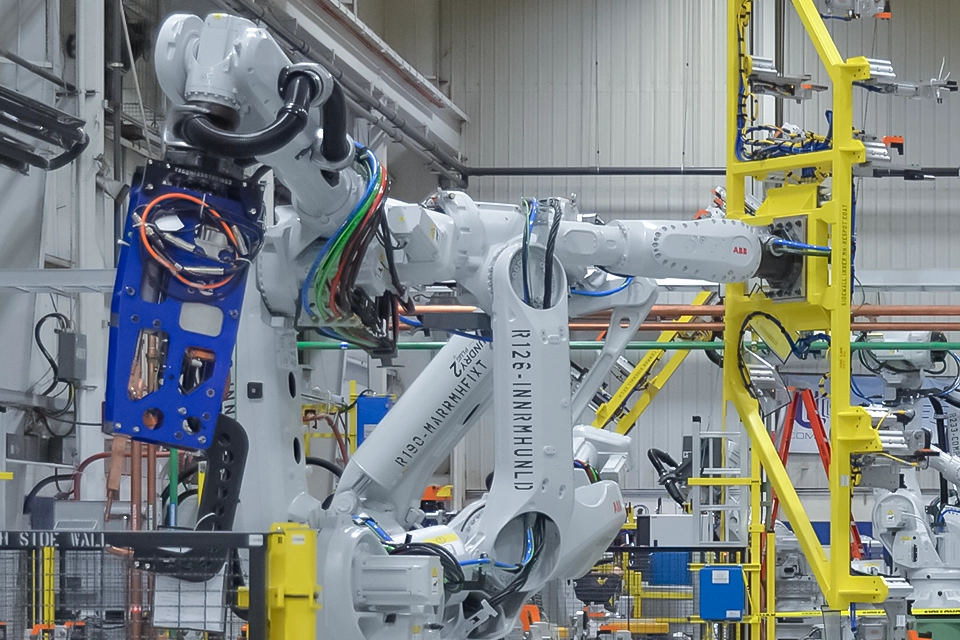

Another area where robotics is widely used in the automotive industry is in the assembly line. Robotics technology has made it possible to automate tasks such as painting, and installing interior and exterior components. This has increased the efficiency and accuracy of the production process, reducing the risk of human error and improving the overall quality of the vehicles.

Many of the processes in the automotive industries are carried out by larger models of robots. Of course this means a lot of great movements, which requires flexible robots that can handle these processes. With large movement comes a lot of stress on the peripheral equipment. Thankfully RSP provides a lot of field-proven parts to ensure functionality, which results in a better over all economy.

Generally you can say that the automotive industry has higher demands when it comes to validation and certifiactions of robot peripheral products. This is why it is important that we as a supplier have good relations with both the robot manufacturers, line builders and the end customers to ensure validation and functionality. RSP are always very structured when it comes to understanding the project. Thanks to this, and our close colaboration with every key player in the project we can ensure to offer the right products with the right functionality.

Other types of common robotic processes in automotive industry are glueing, riveting and rolling.

In addition to improving the production process, robotics has also led to the development of new technologies, such as autonomous vehicles. These vehicles are equipped with sensors and advanced software systems that allow them to navigate roads and highways without human intervention. The use of robotics technology in the development of autonomous vehicles has made it possible to create vehicles that are safer, more efficient, and more convenient to use.

Another significant benefit of robotics technology in the automotive industry is its impact on the workforce. Robotics has made it possible to automate tasks that were previously performed by human workers, freeing up employees to focus on higher value-adding activities such as design, research and development, and customer service. This has also resulted in the creation of new jobs in fields such as robotics engineering and data analysis.

Challanges now, and in the future

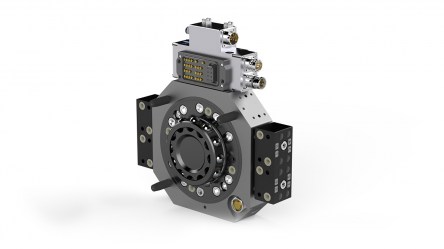

The cost of a car body is very expensive, which means that any unpredicted stops in production can have devastating consequences. Therefore, to maintain high uptime is probably the most important challenge. This requires well documented products, access to CAD-files and technical support, and a strong relation with suppliers when it comes to service and after market. RSP will always have this as a top priority which is why we handle this kind of projects very well. And of course safety is the big thing right now. From RSP:s point of view we are happy to provide tool changers according to Cat 3 Pl d (performance level d).

Despite the many benefits of robotics technology in the automotive industry, there are also challenges associated with its use. One of the main challenges is the high cost of investment in robotics technology, which can be a barrier for smaller companies and start-ups. In addition, the implementation of robotics technology requires specialized skills and training, which can be a challenge for companies that lack the necessary resources.

The future challenges of automotive industry are hard to predict. But we can see that wireless transmission is one thing. The demand of transfering bus signals without cables is high and RSP are proud to be a driving force in the development of this.

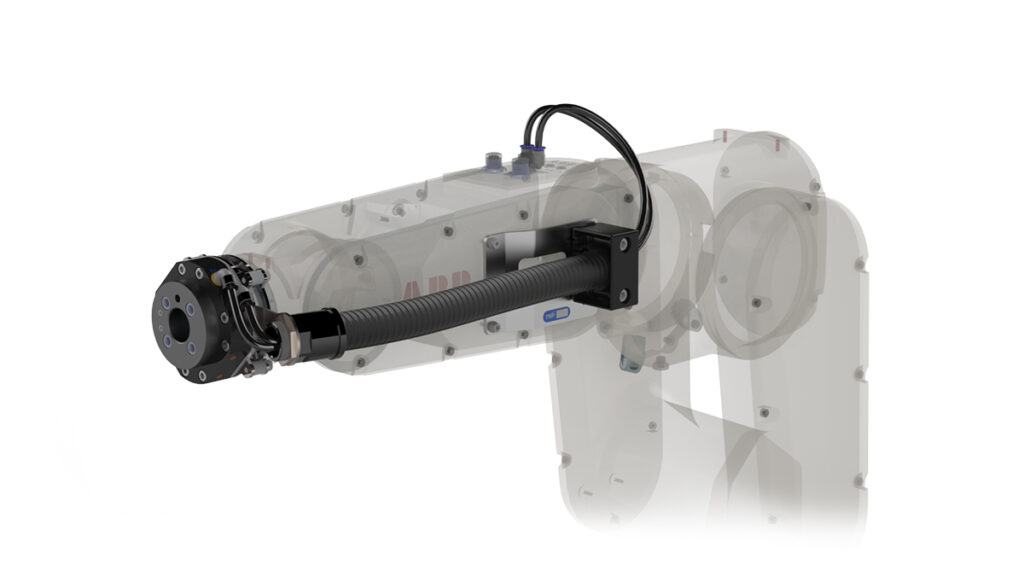

Watch this video about the tool changers from RSP, the unique TrueConnect locking system. Here you can se our Moduflex tool changer with integrated safety along with our tool parking system TPS400. This is the ultimate solution for spotwelding.

Robot System Products – Technology and solutions

Despite the challenges, the use of robotics technology in the automotive industry is set to continue to grow and evolve in the coming years. Advances in robotics technology and the increasing demand for autonomous vehicles are likely to drive further investment in the sector. Companies that embrace robotics technology and invest in their workforce will be well positioned to reap the benefits of this growing industry.

From RSP:s side our flagship product, the Moduflex Tool changer with integrated safety is with it’s unique and patented solution hopefully set to industry standard in the future. Along with our Tool parking system – TPS400 we provide a great solution for not only bodyshops but for all major lines where robots are commonly used. The combination of a “safe” tool changer handling big spotwelding guns and a stable and secure parking system that protects the tooling when it is not used at the moment is an investment with a good ROI.

Economic values and technical advantages from RSP

At Robot System Products we have our roots in the robot world. With years of experience and knowledge we can make sure to give you the best support and solutions in technical assistance, development and investment processes. By having close communication with the robot manufacturers we provide systems that are top-of-the-line well proven. We also provide a range of various patented solutions that ensure you as a customer to get more values in your automation investments.

Higher capacity

Less maintenance costs

Lower investment cost

Flexible solutions

Products suitable for automotive industry

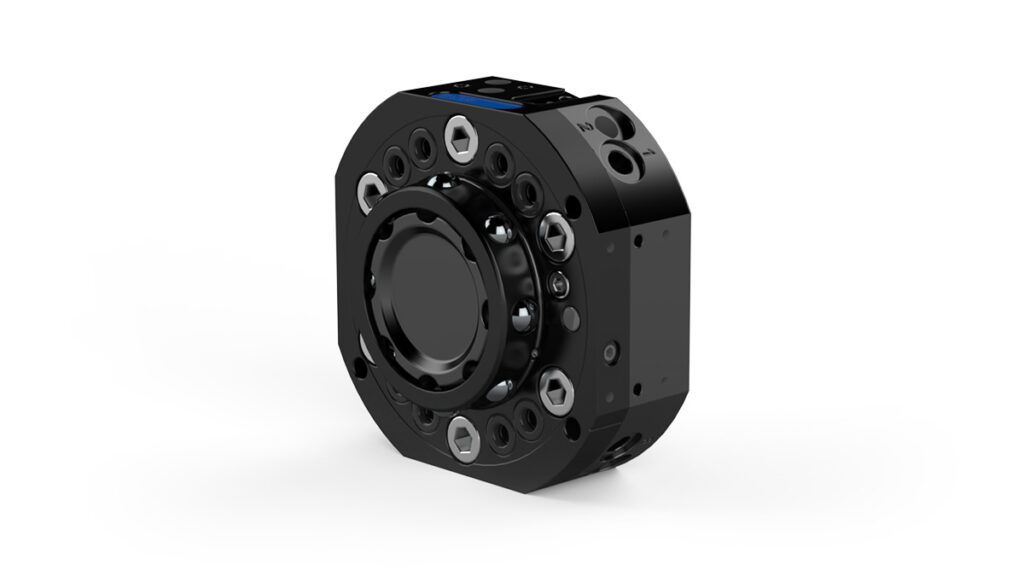

Moduflex TC

The moduflex tool changer with integrated safety is the perfect unit for the automotive industry. A trusted piece of engineering.

Modular TC

Our smaller models of tool changers that are modular and can easily be adapted to your specific robot application demands.

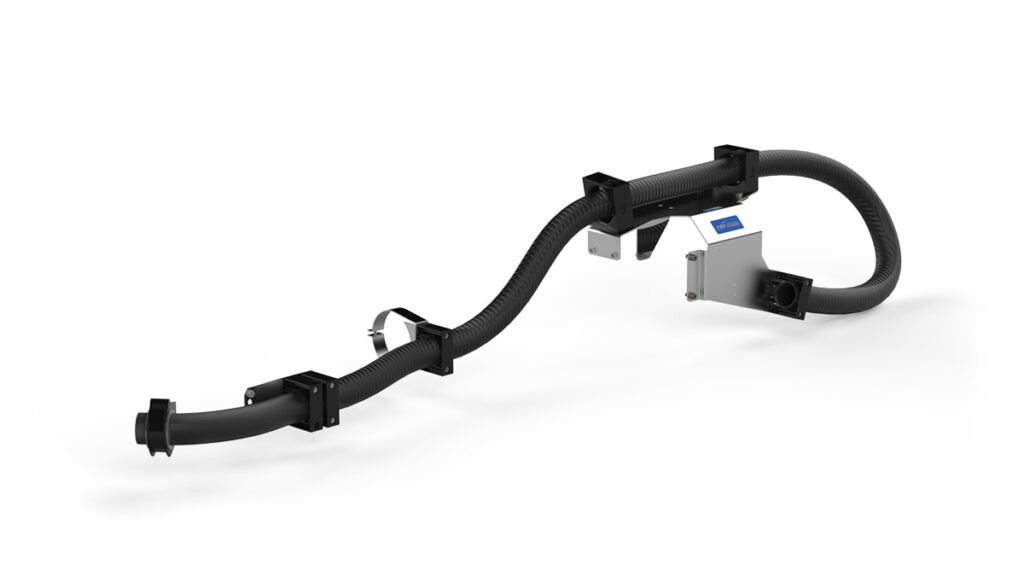

Hose packages

Our standard assortment of hose packages involve more than 100 robot models. Parts for building your own package are also available.

Tool Parking

Tool racks designed for you. A sturdy parking station keeps your tools well protected and in order while they wait to be switched in.

Tool Systems

Complete dress packs for your robot model. An optimized system with quick installation and low maintenance making it a flexible solution.